Menu

Efficiency in industrial production results from a complex interaction of various elements, including human, organizational, and structural aspects, including facilities and machinery. The guarantee of product quality, timely delivery, and customer satisfaction are strongly influenced by the level of control that can be applied throughout the production flow, from mechanical processing and component selection to packaging the finished product ready for shipment.

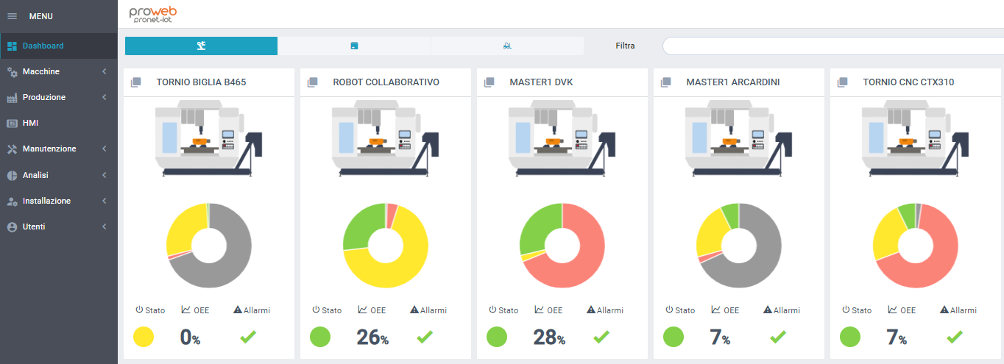

To thoroughly document and control our production process, in IDRAL we have adopted an innovative solution through the implementation of a Manufacturing Execution System (MES). This dynamic software allows the management and control of production orders, designed to adapt to the needs of each department. Following the guidelines of Industry 4.0, the MES is connected to the company’s management system, receiving production orders and managing their execution through direct connections (automatic machines for mechanical processing or assembly) and a WEB interface on PCs and tablets distributed to the operators.

Connected automatic machines, including collaborative robots and mechanical processing devices, interact with the company network, exchanging real-time data regarding their status (in operation, waiting, etc.) and other information, including the number of pieces produced, the running work program, and any alarms. Processing times are automatically recorded throughout the day, and the web interface allows checking the status and productivity of the machines even remotely.

A section of the MES is dedicated to machinery maintenance: an agenda can be set for routine and extraordinary checks, monitoring essential activities to ensure department productivity and minimize machine downtimes.

Manual activity represents a significant part in organizing production activities at Idral; the precision of records and the attentiveness of personnel are crucial to ensuring consistent and useful data for order scheduling and statistical analysis.

Once orders are assigned to work centers (such as the assembly bench), operators record partial processing times for each order and the pieces produced on tablets. From the same web interface, they can access assembly drawings, testing parameters, and any specific instructions for the item in production. Through a dedicated button, they can report a production issue (such as a faulty or insufficient components) or a quality issue (such as aesthetic defects). Operators in the mechanical processing department manually record on tablets the periodic dimensional checks performed on items in production and any detected non-conformities.

All data collected from tablets can be analyzed by the software to obtain as realistic statistics as possible on different work centers and evaluate production times for programming and production cost assessment purposes. Whenever a production issue is detected, an informative email is automatically sent to the department manager, and the order is blocked in the MES awaiting authorization for recording. Only the department manager, once the extent of the problem is verified, can authorize the order’s release and recording in the company’s management system.

Downtime statistics can be easily exported from the MES software: based on this, corrective actions are evaluated to prevent or minimize the likelihood of the same issues recurring in the future.

The accurate management of production resources and their effective integration are fundamental aspects for IDRAL, representing our constant commitment to the future. Our dedication to technological innovation and continuous research allows us to offer increasingly efficient and reliable solutions. We firmly believe that only through a constant process of improvement, we can guarantee quality products and satisfaction for our customers. We are here for you! For more information or personalized support, feel free to contact us. Our team is ready to assist you and provide all the answers you need.

By Alessandro Creola

Production Manager

Keep up to date

Idral S.p.a. a socio unico – Via Isei 8/10 – 28010 Gargallo (NO) Italia

Cap. Soc. € 660.000 i.v. | C.F. e Iscr. reg. imp. NO 00124610031 | REA n° 104665 | C.C.I.A.A. Novara | P.IVA 00124610031